Atomic layer deposition is a method of producing and depositing high-quality ultra thin films in a controlled manner. The significance of atomic layer deposition is not restricted to providing ultra thin films; it also provides 3D structures which can be covered with a firm coating for high aspect-ratio structures. Atomic layer deposition is applicable in industrial and research industries. Atomic layer deposition is just like CVD. It is totally dependent on the reactant design and has been developed for commercial use. It is first being used in Finland. It is also known as a special kind of chemical vapour deposition. It is used for the preparation of high-quality thin films on three-dimensional structures. This article provides a general overview of the advantages and limitations of atomic layer deposition.

Basic characteristics of the atomic layer deposition

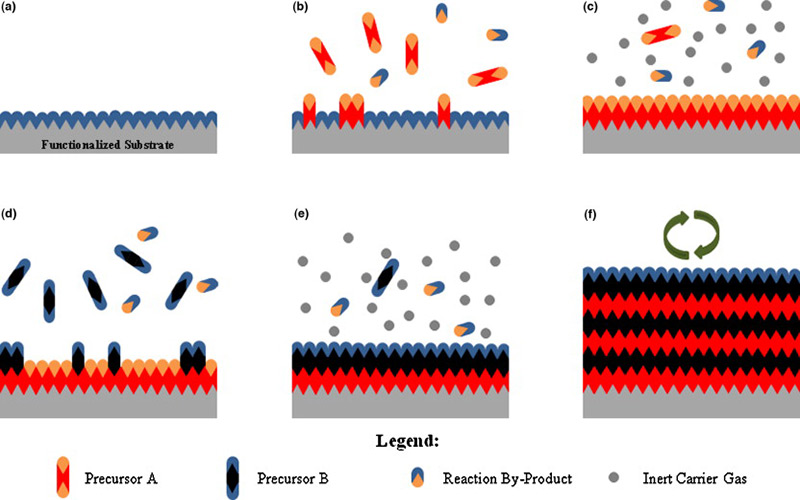

Atomic layer deposition is considered a one-time reaction cycle. To achieve the desired results, the atomic layer deposition parameters such as reactant, substrates, and temperature must be adjusted. It focuses on high quality films that have thickness accuracy and give one atomic layer at a time. It is a suitable method for inorganic material layers and some metals. Atomic layer deposition has highly reactive precursors and must not decompose at the process temperature. Atomic layer deposition has various reactors like closed system chambers, open system chambers, semi-closed system chambers, and semi-open system chambers, and each reactor has different features and properties. For more information, click Atomic layer deposition.

There is a requirement for precursors in atomic layer deposition. It involves ligand precursors and metallic precursors. A Ligand precursor is used in preparing the surface for the next layer, and it basically defines the type of material to grow. A metallic precursor is highly reactive and thermally stable. It helps in fulfilling the need for self-terminating reaction. It provides sufficient priority and does not involve any self-decomposition. It helps in not dissolving the film into substrates. The uniformity in the atomic layer deposition is ensured by the saturation process. In atomic layer deposition, thickness is controlled by counting the number of reaction cycles. Atomic layer deposition is used in magnetic heads. For more information, go to https://www.atomiclayerdeposition.com/.

The benefits and drawbacks of atomic layer deposition

There are various benefits of using atomic layer deposition. It has a self-limiting growth process and has the promising feature of providing ultra thin films with a high aspect ratio. In atomic layer deposition, there is no requirement to control reactant flux homogeneity and it provides the thin film with proper uniformity and conformity. It gives dense, quality, uniform, and pinhole-free films with the control of atomic level composition. In atomic layer deposition, the thickness of the film is managed by the number of deposition cycles. It has surface exchange reactions by the usage of separate dosing of reactants. Along with its benefits, there are some drawbacks to atomic layer deposition. It provides low effective deposition rates. It is to be noted that if there is too much flow, then it will lead to clogging or valves. If there is too low flow, it leads to underperformance. It used excess equipment.

Conclusion

Atomic layer deposition is a technique that provides high quality thin films with uniformity and conformity. It had promising features and had high aspect ratios. There are various advantages of atomic layer deposition that make it suitable to be applied in industrial and research applications. Atomic layer deposition is an important process, and thickness is managed by the reaction cycles. It is a great solution for producing conducive thin films. It is a simple yet flexible control. The limitations of atomic layer deposition are very small as compared to its benefits. It is recommended to use the technique of atomic layer deposition for producing thin films of high quality.

Follow – https://techhipo.com for More Updates