Extensive medical research and technology development is required to find the complex cure to fatal infection like COVID-19. Additive manufacturing has come out as one of the promising technologies in this sector. The technology promises to be the epitome of speed and precision with its remarkable accomplishment in curing COVID-19 in a short period. Armed with multiple benefits that it offers to humanity, custom 3d printing continues to help eradicate life-threatening diseases from all over the world.

Additive manufacturing helped healthcare institutes and authorities balance the shortage of medical equipment and PPEs globally. With the help of 3D printing, medical devices were possible to create in a single day instead of weeks. In this way, more medical staff could be trained and deployed faster than ever before. The technology helped nations save time and money and improve public health.

How does 3d printing for healthcare help during the COVID-19 peak?

3d print solutions play a commendable role in delivering safe patient care. Technology has emerged as a critical element to implement infection control practices while minimizing exposure to healthcare workers. Below are some key ways additive manufacturing help healthcare workers:

PPE kit manufacturing:

PPEs are mandatory to prevent healthcare workers from falling ill due to contamination. But the tools, masks, gowns and other equipment needed to be replaced daily. It puts additional pressure on existing healthcare facilities, which are already overcrowded. With 3D printing, these medical devices are quick to manufacture for better infection control practice at the hospital.

During the COVID-19’s peak, there was a dire shortage of PPE kits. 3D printing proved its mettle by offering quick relief to the healthcare staff. With the help of this technology, PPE kits are easy to manufacture and are also provided with increased user safety and superior protection.

Medical equipment manufacturing:

3D printers played a crucial role in producing a large portion of all medical equipment used at health care facilities during COVID-19. For example, it helped create patient charts, provide bedding arrangements, operate surgical tools, set up x-ray machines, and other things required during the peak infection epidemic.

The health care workers were able to better manage infection control practices with the help of 3D printing. However, the production and manufacturing of medical devices proved to be a cumbersome task during COVID-19. 3D printers provided quick relief since these machines are suitable for medical device sterilization purposes in an ISO Class 5 environment.

3d print on demand service for ventilator valves:

To meet the shortage of ventilator valves, healthcare institutions used online 3d printing services. It helped supply critical valves to several hospitals to save the lives of patients who need ventilator support. In addition, reputable companies saw this as an opportunity and used additive manufacturing to develop custom 3d printed medical devices.

Companies printed and supplied customized life-saving medical equipment like plastic catheters, breathing tubes and disposable components like syringes. The technology changed the face of healthcare by offering quick relief during the COVID-19 epidemic. During the COVID’s peak, there was a severe shortage of working ventilators. 3D printing proved to be a powerful technology for disaster relief by supplying the critical parts required for proper ventilator functioning.

Custom-made face shields:

Companies and healthcare institutes used 3d rapid prototyping services for creating custom-made face shields. These are used to protect doctors, nurses and other staff in direct contact with the infected patients.

The face shields were critical for protecting COVID-19. 3D printing helped produce thousands of these shields within a brief period. In addition, the technology created custom-sized disposable door handles that were easy to change to maintain hygiene and prevent further contamination. Several leading companies, including Karv Automation, offered 3d printing for medical equipment manufacturing to fulfil the shortage.

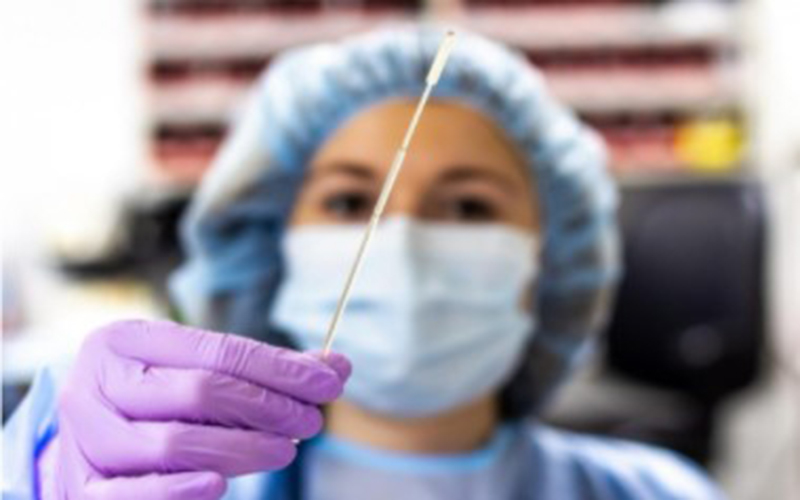

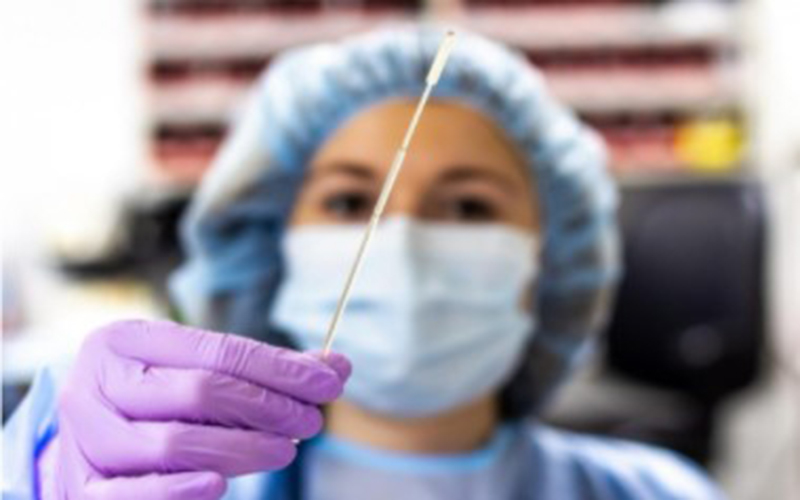

Specimen collection kit:

Medical practitioners could print anatomical charts, specimen collection kits and other crucial medical tools required during the COVID-19 outbreak. The condition was further deepened by the lack of cleanroom facilities which are mandatory for proper device manufacturing. 3D printing helped provide infection control at healthcare institutions by creating custom-sized disposable components that could be easily disposed of after each use without causing any cross-contamination.

The 3d prototyping service played a crucial role in helping the government address the COVID-19 epidemic. They produced various critical medical equipment needed to prevent contamination caused due to poor infrastructure setup. As a result, additive technology has become a promising solution for better patient care, especially during epidemics like COVID-19.

Streamlining the affected supply chain:

With thousands of suppliers and manufacturers running behind schedule, this advancement needed to step in. 3d print service was employed as a solution due to its quick prototyping and production of custom products.

The crisis once again proved how 3D printing could mitigate the damage caused by natural disasters by providing critical supplies for healthcare institutions. In addition, the affected supply chain provided an opportunity for companies worldwide to offer practical solutions using additive manufacturing technologies.

3D printing companies worked with various institutes to help create customised devices to fit every individual’s needs. It helped curb cross-contamination at medical facilities, resulting in fewer deaths during COVID-19.

Custom-designed air filters:

Companies that provide 3d printing services use this technology to help manufacture highly efficient air filters. These were designed according to the patient’s needs and could be easily installed on ventilators during COVID-19 outbreaks.

The epidemic brought about a drastic change in the healthcare industry by focusing on infection control at various medical institutions. As a result, the number of deaths reduced significantly after these custom 3D printed devices were supplied across healthcare facilities worldwide.

Future of 3d printing in the medical domain

3D printing has come a long way from being just another prototyping technology to having a promising future in the medical field. We will see a lot more impact caused due to 3D printing in the years to come. This technology has enabled the design of highly effective devices personalized for each patient’s use.

3d printers can print highly accurate molds, which are ideal for custom-made prosthetics. It may even change the way medical operations are performed around the world at some point.

Further, companies specialize in providing 3D printing services by offering different solutions across industries under one roof. It will help speed up product development and reduce costs significantly, which is essential for any company looking to impact a global stage.

Author’s Bio:

KARV Automation offers on-demand 3D Printing and Additive Manufacturing solutions for Industry 4.0. From prototyping to mass manufacturing, we deliver quality products at affordable costs. We are a full-manufacturing company that offers services worldwide. From product development to fundraising and packaging, we offer all manufacturing solutions to scale your business. With our platform, customers can get instant quotations, expected lead times, and feedback on the go.

Follow – https://techhipo.com for More Updates